DEFENCE ORGANISAITIONAL EXPERIENCE

Since 1985 worked as Junior Engineer on board front line war Ships of Indian navy.

KEY RESPONSIBALITIS:

Engine Room watch keeping on 18 Cylinder oppose Piston, two stroke Turbo

Super changer, Paxman Deltic Main Diesel Engine, HP – 3440.

Watch keeping on 16 Cylinder Oppose Piston two stroke Turbo Super charged

Main Diesel Engine HP- 6000

Watch keeping on A.C. Plants with cooling capacity of 55000 K.Cal /hr.

Since 1992 taken up responsibilities as 4th engineer on board Flag Ships.

Maintenance of Main diesel Engines with capacity of 6 cylinder 4 stroke, Kirloskar

Cummins HP- 165.

Maintenance on Gas Turbines with straight flow, two spool co- axial type.

Weekly maintenance on Diesel Alternators of 88 KW.

First week training- (P-days)-

Intense week of physical conditioning. Recruits take their initial swim,

qualification test and learn military drill, the details of rank and rating, and the Navy

core values.

Week Two

During Week Two, recruits learn the Navy chain of command, custom and courtesies, and basic watch standing

Week Three

Consists of hands on training. Recruits learn laws

of armed conflict, personal finance, basic seamanship, shipboard communication, and Navy ship and aircraft identification.

Week Four

Mostly consists of weapons training. Recruits gain

familiarity with the M9 pistol. Sometime during the week, recruits receive a classroom lecture on firearms safety and operation of the M9.

Week Five (Hell week)

Consists of learning more drill instructions needed for the military drill assessment

Week Six– Recruits learn shipboard damage control and firefighting skills.

Week Seven– It is the last week of Navy Basic Training in which recruits must participate in

Battle Stations and pass the test to become sailor

Engine Room watch keeping on 18 Cylinder oppose Piston, two strokeTurbo Super changer, Paxman Deltic Main Diesel Engine, HP – 3440

Watch keeping on 16 Cylinder Oppose Piston

two stroke Turbo Super charged Main Diesel

Engine HP- 6000.

Watch keeping on A.C. Plants with cooling

capacity of 55000 K.Cal /hr.

Maintenance of Main diesel Engines with capacity of 6 cylinder 4 stroke, Kirloskar Cummins HP- 165.

Maintenance on Gas Turbines with straight flow, two spool co-axial type. Weekly maintenance on Diesel Alternators of 88 KW.

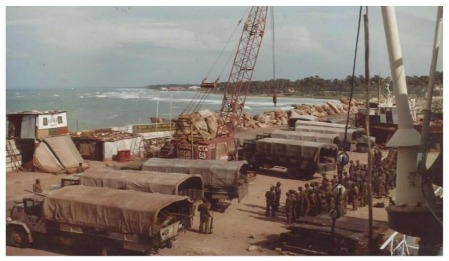

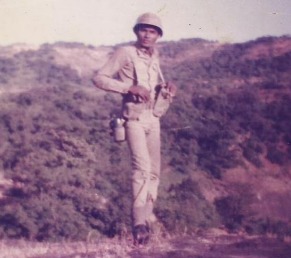

On Board Ship INS DB T55 in the Year (1990)